ABOUT GLOBAL ALUMINIUM EXTRUSION

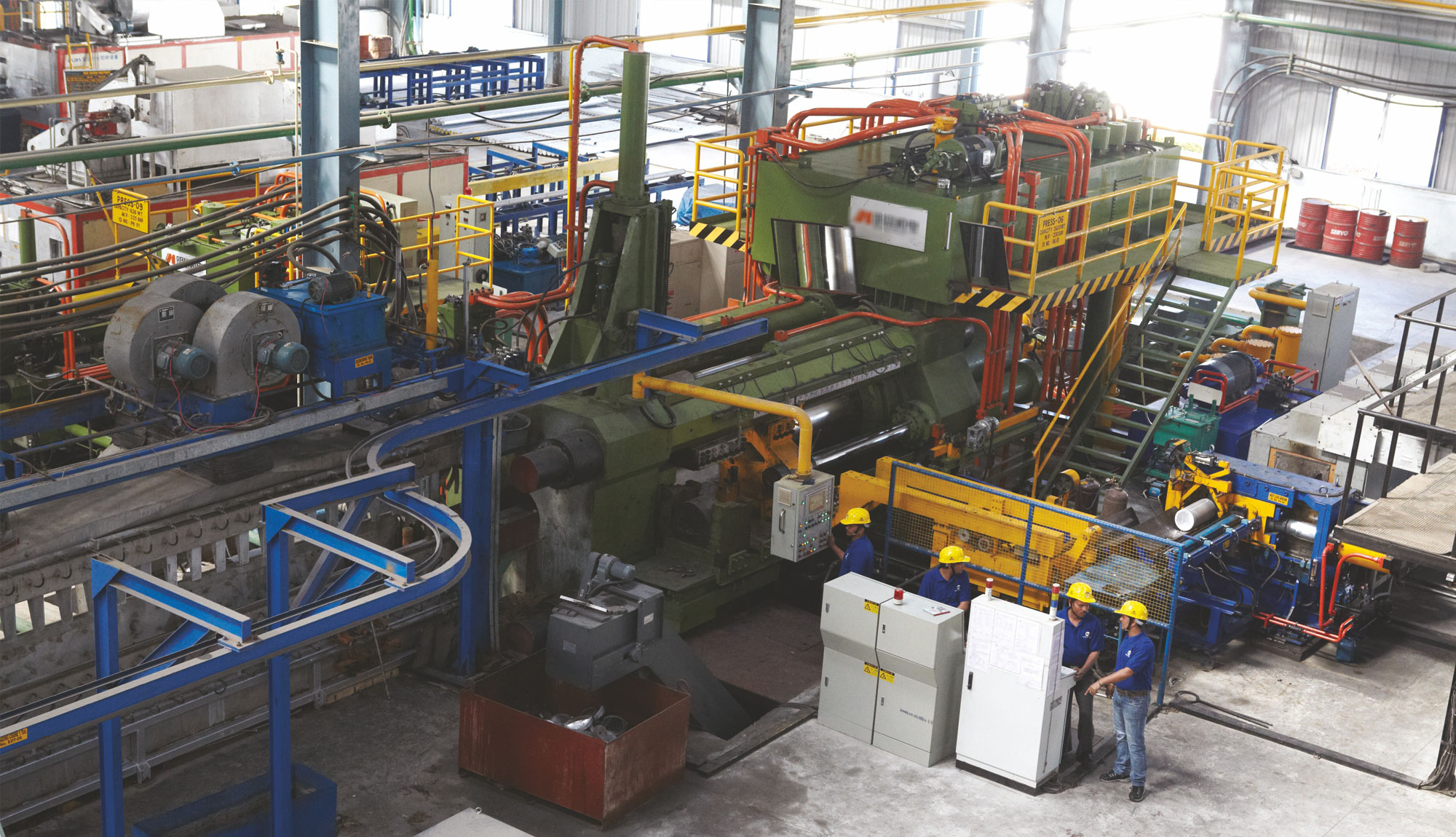

GLOBAL ALUMINIUM PRIVATE LIMITED, a Company incorporated under the erstwhile provisions of Companies Act, 1956, is an ISO 9001-2015 & ISO 14001:2015 Certified by TUV SUD, engaged in manufacturing of premium quality Aluminium profiles. We operate 2 advanced automated aluminium manufacturing units strategically located very close to each other at Kallakal Village of Medak district in the state of Telangana.

The infrastructure has been setup with most advanced technologically equipped machineries and 100% power back up facilities. We cater to the intricate global needs with an installed capacity of 50,000 TPA with in house value additions like aluminium extrusion manufacturing , anodizing processes, aluminium powder coating Read More.

ABOUT INDUSTRY

Aluminium – the third most abundant element in the earth’s crust finds its implementation in many sectors due to its environment and user -friendly nature – in Building and Construction (B&C), power sector, automotive, packaging, household appliances etc. The surge in the demand of this youngest metal of the non-ferrous metal industry is indicated to the escalating infrastructural development of the country.

According to a recent issue of the European Journal of Business and Management, published by International Institute for Science, Technology and Education, the overall consumption of aluminium in India is projected to be about 10 million tonnes by 2020.

Aluminium is the second most used metal in the world after steel with an annual consumption of 88 Million Tonnes (including scrap). Aluminium consumption in India at 2.5 kg per capita is much below the global average of 11kg per capita Read More.

PRODUCTS

01

ALUMINIUM EXTRUSION

Aluminium extrusion is the process of pumping aluminium alloys streamlined through pre-set and shape defined dies to gain a

02

ANODIZING

Anodizing is the electrolytic oxidation process in which the surface layer of metal is transformed to allow it to provide protective, decorative or functional

03

POWDER

COATING

Global Aluminium offers comprehensive fabricating equipment including press brakes, shears, panel lamination lines,

04

MACHINE

SHOP

Global Aluminium offers comprehensive Machine Shop and has built in facilities for including CNC’s, VMC’s, Drilling Machines,

WHY CHOOSE US?

OUR TOP SEGEMENTS

NEWS ROOM

ANNUAL RETURNS

GET IN TOUCH

If you have any questions, just drop an email, and we will answer you shortly.

Procurement

We encourage all the relevant vendors, suppliers to approach for any partnerships.

Best Aluminium extrusion manufacturer in India | Top Aluminium Extrusion Companies in India | Top 10 aluminium extrusion companies in India

Best Aluminium extrusion companies in India | Aluminium extrusion profiles catalog l Top aluminium extrusion exporters in India

ISO 9001-2015 & ISO 14001:2015 Certified by TUV SUD, engaged in manufacturing of premium quality Aluminium profiles.