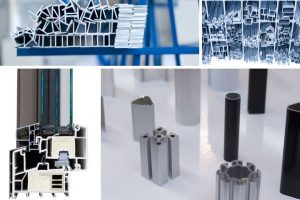

Aluminum is a versatile metal with various applications, including construction, transportation, packaging, and consumer goods. One of the critical aspects of using aluminum in these applications is selecting the right aluminum section profile. The aluminum section profile refers to the shape of the aluminum extrusion, and it can determine the mechanical properties, strength, and functionality of the aluminum component. In this blog, we will discuss how to choose the right aluminum section profile for your application.

Consider the Functionality

Before selecting an aluminum section profile, it is crucial to understand the functionality of the aluminum component. The functionality can determine the size, shape, and thickness of the aluminum extrusion. For example, if the aluminum component needs to be structurally sound, you may require a thicker and heavier aluminum section profile. However, if the component is for decorative purposes, a lighter and thinner aluminum section profile may suffice.

Determine the Load Requirements

Another critical factor to consider when choosing an aluminum section profile is the load requirements. The load requirements refer to the amount of weight or pressure that the aluminum component can withstand. The load requirements can determine the strength, stiffness, and deformation of the aluminum extrusion. For example, if the aluminum component needs to support heavy loads, you may require an aluminum section profile with a thicker and more massive cross-section.

Evaluate the Design Requirements

Evaluate the Design Requirements

The design requirements of the aluminum component can also influence the selection of the aluminum section profile. The design requirements refer to the shape, size, and aesthetics of the aluminum component. For example, if the aluminum component needs to be curved or bent, you may require an aluminum section profile that can be easily shaped without compromising the strength or integrity of the extrusion.

Consider the Manufacturing Process

The manufacturing process can also influence the selection of the aluminum section profile. The manufacturing process refers to the process of converting the aluminum billet into an extruded profile. The manufacturing process can determine the complexity, tolerance, and finishing of the aluminum extrusion. For example, if the manufacturing process requires high precision and tight tolerances, you may require an aluminum section profile that can be easily extruded with minimal distortion or defects.

Evaluate the Cost

The cost of the aluminum section profile can also influence the selection. The cost can depend on the size, shape, complexity, and finishing of the aluminum extrusion. For example, if the aluminum component requires a highly customized section profile with intricate designs and finishing, the cost may be higher than a standard section profile.

Conclusion

Choosing the right aluminum section profile is crucial for ensuring the functionality, strength, and aesthetics of the aluminum component. By considering the functionality, load requirements, design requirements, manufacturing process, and cost, you can select an aluminum section profile that meets your needs and specifications. It is essential to work with a reputable aluminum extrusion company that can provide expert advice and guidance on selecting the right aluminum section profile for your application.