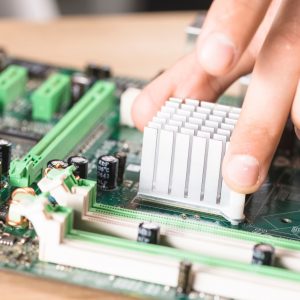

Aluminum extrusion profiles are a popular choice for a variety of industries, including the electronics industry. This is because aluminum is lightweight, strong, durable, and corrosion-resistant, making it an ideal material for a range of applications. One such application is heatsinks, which are crucial components in electronic devices that dissipate heat and prevent overheating.

What is aluminum extrusion?

Aluminum extrusion is a process used to create complex shapes and designs by forcing heated aluminum through a die. The resulting product is an extruded profile, which can be cut to the desired length and shape for use in a wide range of applications. The process of aluminum extrusion is efficient and cost-effective, making it a popular choice for a range of industries.

The benefits of using aluminum extrusion profiles as heatsinks:

There are many benefits to using aluminum extrusion profiles as heatsinks in the electronics industry. Here are just a few:

Efficient heat dissipation

Aluminum is an excellent conductor of heat, meaning that it can transfer heat away from electronic components quickly and efficiently. This is essential in the electronics industry, where overheating can cause damage to sensitive components and even lead to fires.

Lightweight and durable

Aluminum is lightweight and durable, making it an ideal material for use in electronics. It can withstand a range of temperatures and is resistant to corrosion, making it a low-maintenance option for electronic devices.

Versatile

Aluminum extrusion profiles can be created in a range of shapes and sizes, making them ideal for use in a wide range of electronic devices. They can also be easily cut and customized to fit specific applications, making them a flexible option for electronics manufacturers.

Cost-effective

Aluminum extrusion is an efficient and cost-effective process, making it an affordable option for electronics manufacturers. This means that heatsinks made from aluminum extrusion profiles can be produced at a lower cost than those made from other materials, without compromising on quality.

Applications of aluminum extrusion profiles in heatsinks:

Aluminum extrusion profiles are used in a wide range of heatsink applications in the electronics industry. Here are just a few examples:

Computers

Computers

Computers generate a lot of heat, particularly when running demanding applications or when using high-performance components. Heatsinks made from aluminum extrusion profiles are used to dissipate this heat and prevent damage to internal components.

LED lighting

LED lighting generates heat, which can reduce the lifespan of the LED and affect its performance. Aluminum extrusion profiles are used to create heatsinks that can dissipate this heat and help to prolong the lifespan of the LED.

Power electronics

Power electronics generate a lot of heat, particularly when operating at high power levels. Heatsinks made from aluminum extrusion profiles are used to dissipate this heat and prevent damage to internal components.

Audio amplifiers

Audio amplifiers generate heat, particularly when operating at high power levels. Heatsinks made from aluminum extrusion profiles are used to dissipate this heat and prevent damage to internal components.

Automotive electronics

Automotive electronics

Automotive electronics are subjected to a range of temperatures, making it essential to use heatsinks that can withstand these conditions. Heatsinks made from aluminum extrusion profiles are ideal for use in automotive electronics, as they are lightweight, durable, and resistant to corrosion.

In conclusion, aluminum extrusion profiles are an excellent choice for heatsinks in the electronics industry and Global Aluminium have been serving customized aluminium extrusion profiles for heatsinks since two decades, to some of the reputed electronic companies across world. As technology continues to advance and electronic devices become more complex, the demand for high-quality heatsinks made from aluminum extrusion profiles is likely to continue to grow.